The climate and environmental adaptability tests of industrial security camera module

The analysis software of the recorder is installed in the general Chinese operating system, and the test computer is connected with the recorder through the communication interface according to the use requirements. The recorder is tested for various functions such as data reading, query, statistics, parameter setting, operation authority setting, etc.

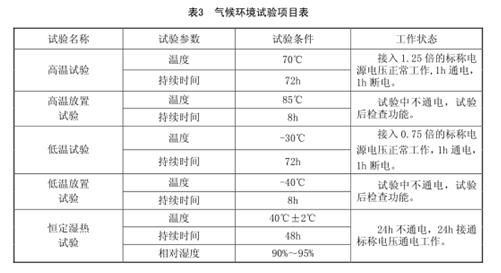

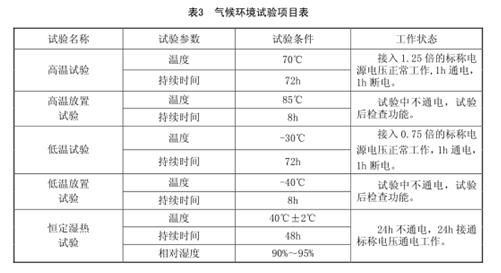

5.8 climate environment adaptability test

See Table 3 for test parameter settings.

5.8.1 high temperature test

5.8.1.1 test equipment

The test equipment shall meet the requirements of GB / T 2423.2.

5.8.1.2 test method

Preprocessing: the recorder is connected to the signal according to the normal working mode and connected to 1.25 times of the nominal power supply voltage to work normally.

Put the connected recorder into the high-temperature test chamber and keep it for 72 h at 70 ℃ ± 2 ℃. During this period, the recorder is powered on for 1h, disconnected for 1h, and continuously powered on and off until the end of the test. During and after the test, check the appearance structure, main functions and data record of the recorder.

5.8.2 high temperature storage test

5.8.2.1 test equipment

The test equipment shall meet the requirements of GB / T 2423.2.

5.8.2.2 test method

Put the connected recorder into the high-temperature test chamber and keep it at 85 ℃± 2 ℃ for 8h. After the test, return to room temperature, turn on the nominal power supply voltage and connect the signal to work normally. After the test, the external structure, main functions and data records of the recorder were checked.

5.8.3 low temperature test

5.8.3.1 test equipment

The test device shall meet the requirements of GB / T 2423.1.

5.8.3.2 test method

Preprocessing: the recorder is connected to the signal according to the normal working mode and connected with 0.75 times of the nominal power supply voltage.

Put the connected recorder into the low-temperature test chamber and lower it at - 30 ℃± 2 ℃ for 72h. During this period, the recorder is powered on for 1h, disconnected for 1h, and continuously powered on and off until the end of the test. During and after the test, check the appearance structure, main functions and data record of the recorder.

5.8.4 low temperature storage test

5.8.4.1 test equipment

The test device shall meet the requirements of GB / T 2423.1.

5.8.4.2 test method

Put the connected recorder into the low-temperature test chamber and keep it at - 40 ℃± 2 ℃ for 8h. After returning to room temperature after the end of the test, the nominal power supply voltage is switched on and the signal is connected to work normally. After the test, the external structure, main functions and data records of the recorder were checked.

5.8.5 constant damp heat test

5.8.5.1 test equipment

The test device shall meet the requirements of GB / T 2423.3.

5.8.5.2 test method

Pretreatment: the recorder is connected to the signal according to the normal working mode.

Put the recorder (not included) into the test box. The recorder is at dry bulb temperature

When the temperature is 40 ℃± 2 ℃ and the relative humidity is 90% ~ 95% for 24h, the nominal power supply voltage of the recorder is turned on, and it is in normal working state

Keep it for another 24 hours. During and after the test, check the appearance structure, main functions and data record of the recorder.

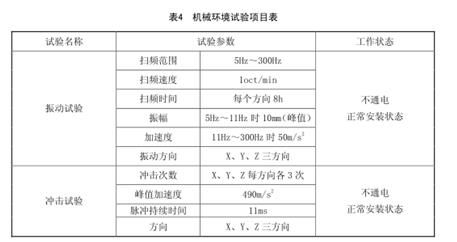

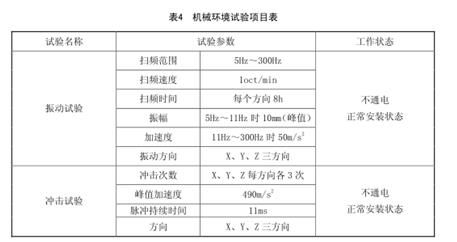

5.9 mechanical environment test

See Table 4 for test parameter settings.

13423810014

13423810014  0755-29433686

0755-29433686  daming@cameras-module.com

daming@cameras-module.com  2/F, Building H, Zhiyihan Industrial Park, Yuanling Village, Shiyan Town, Baoan District, Shenzhen 518108

2/F, Building H, Zhiyihan Industrial Park, Yuanling Village, Shiyan Town, Baoan District, Shenzhen 518108